August 12, 2012

Capacity boost with System TM handling solution

It is 13 years ago that System TM delivered an optimizing cross-cut system to A&J Scott in England which increased their production capacity by 50%. The handling solution that A&J Scott recently invested in from System TM will ensure yet another capacity increase in their production.

Investing in the future

A main focus at A&J Scott is to invest in state of the art production facilities, to support their ability to produce large volumes of consistently high quality products. To provide a massive boost to their production of feather-edge and thin fence boarding, A&J Scott invested in a state of the art System TM handling system with automatic in-feed to their Stenner MHS9 multi-head horizontal resaw and automatic stacking of the finished product.

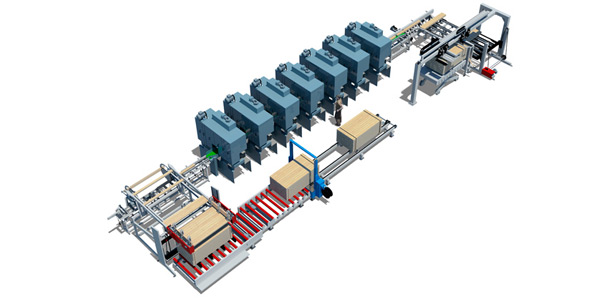

The handling system from System TM

The automatic handling system consists of an automatic feeding system, model Opti-Feed 3000 Push. The feeding system consists of ascissor lift that automatically positions the packs for the pushing unit. When needed, the pushing unit pushes one workpiece layer at a time onto a roller conveyor that is pneumatically lowered for delivery of the layers to a feeding chain conveyor.

The feeding chain conveyor automatically transports and singulates the workpieces to a slanted roller conveyor. This ensures that the workpieces are transported securely along the fence into the Stenner 7 head horizontal resaw, that can split the incoming block into a maximum of 8 boards.

After the Stenner resaw, the split workpieces are kept together as one piece, and transported by a roller conveyor to a turning device that will elevate and turn the workpieces 90°. During the turn, the workpieces will be stopped half way in a vertical position, to allow the sawdust in between the pieces to fall out.

After being turned, the workpieces are buffered into layers before the stacking area. The automatic stacking system consists of an Opti-Stack 3000 that stacks the layers into packs, before strapping and transport of the packs, to the subsequent production.

This handling system enables A&J Scott to run a fully automatic feeding and stacking process that optimizes both their staff and wood resources.