July 30, 2017

Giguère & Morin Inc. in Canada invests in infeed solution

To Giguère & Morin Inc. it was very important that the design comprised a high-efficiency solution capable of keeping a constant flow of workpieces to the ripsaw. One of the challenges in the design phase was the limited space available for the infeed solution, but Giguère & Morin Inc. were very impressed with the initial layout and decided to invest in the System TM solution.

Giguère & Morin Inc.

Giguère & Morin Inc. was established in Canada in 1968 as a manufacturer of customized hardwood components. The company provides components for furniture and kitchen manufacturers and woodworkers needing architectural elements. The facilities of Giguère & Morin Inc. are among the best equipped in the industry, enabling them to create optimal and cost-efficient solutions for their customers.

High capacity and quality

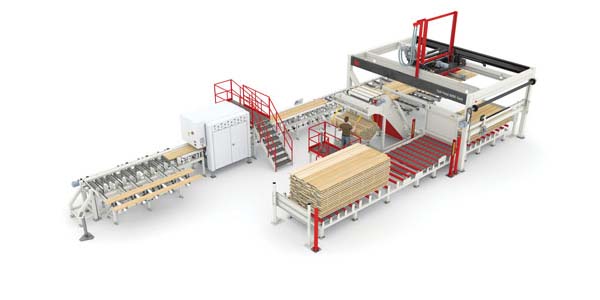

Giguère & Morin Inc. is focused on remaining in the vanguard of their field by offering value-added high quality wood products. The purpose of the investment is increasing production capacity and product quality. One of the recent investments is an vacuum infeed Opti-Feed 6000 Vack, batch feeder and planer outfeed from System TM. This infeed solution will automate the entire infeed process to a planer and ripsaw.

The infeed solution from System TM

The packs are placed on the roller conveyor and transported to the automatic feeding system, Opti-Feed 6000 Vack. The Opti-Feed 6000 Vack de-stacks one layer at a time and creates a batch and transports it through the planer. This solution posed some challenges i. e. the removal of drying sticks. Being aware of the limited space available, System TM developed a system where the sticks are brushed off each layer onto a conveyor. On the conveyor, a door ensures that the sticks stay in position for the stick elevator which transports the sticks into the bundler. Each stick bundle will be transported across the pack roller conveyor and removed by a forklift.

After the planer the workpieces are singulated and fed one by one into the ripsaw. After the ripsaw the workpieces continue in the production of furniture components.

Production efficiency

System TM has enjoyed very much designing this solution and co-operating with Giguère & Morin Inc. It is very important to System TM that the designed solution lives up to the expectations of Giguère & Morin Inc. enabling them to increase the efficiency of their production.