October 21, 2012

Material handling solution for line expansion at Tarkett in Sweden

After delivering a multiple cross-cut system to Tarkett in Hanaskog, Sweden in the 1990’s, they have now decided to expand the line in order to fully utilize the full capacity of the saw line, hence adding extra equipment to the subsequent production.

Designing an automatic feeding system

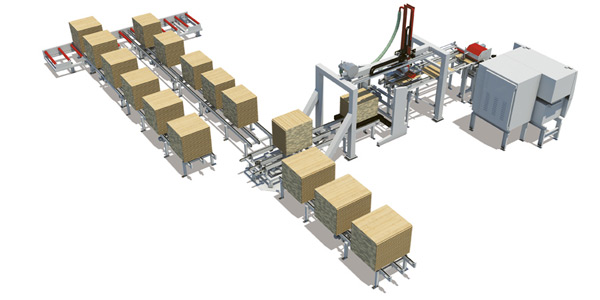

From the beginning, the saw line from System TM was connected to a ripsaw line, and one of the challenges of incorporating the new capacity, was to create a feeding system automatically transporting the cut workpieces to the new ripsaw line. System TM designed the best solution for this, and was therefore chosen by Tarkett to provide the feeding solution. After adding the second ripsaw line to the multiple cross-cut system, the packs can be either automatically transported to a storage facility, to the existing, or to the new ripsaw line.

The feeding system

The storage facility will receive or deliver packs of workpieces to and from the line with the aim of retaining an optimal production flow. If needed it is also possible to pick up or supply packs from an external storage facility.

Packs going to the new ripsaw line are automatically transported through a buffer area into a turning device, which rotates thepacks 90° to give the packs the correct position for the ripsaw. If needed, it is here also possible to pick up or supply packs, from an external storage facility. After the rotation, a pack lift will raise the packs to the de-stacking area. A feeding system model Opti-Feed 1000 Vack will, when needed,automatically pick up one layer at a time, and place the layers on a crosschain conveyor. From the cross chain conveyor, the layers will be singulated into workpieces, and fed one by one into a ripsaw line.

Secure handling of the workpieces

What is very important for Tarkett is secure handling of the workpieces from the packs and to the ripsaw line, retaining a high uptime and capacity. System TM has designed the Opti-Feed 1000 Vack to gently handle packs of raw material, without losing any capacity. Furthermore it is very important that the workpieces are fed very precisely into the ripsaw for a perfect straight cut, and the handling solution from System TM ensure just that.