OPTI-FEED 6000 VACK

Opti-Feed 6000 Vack

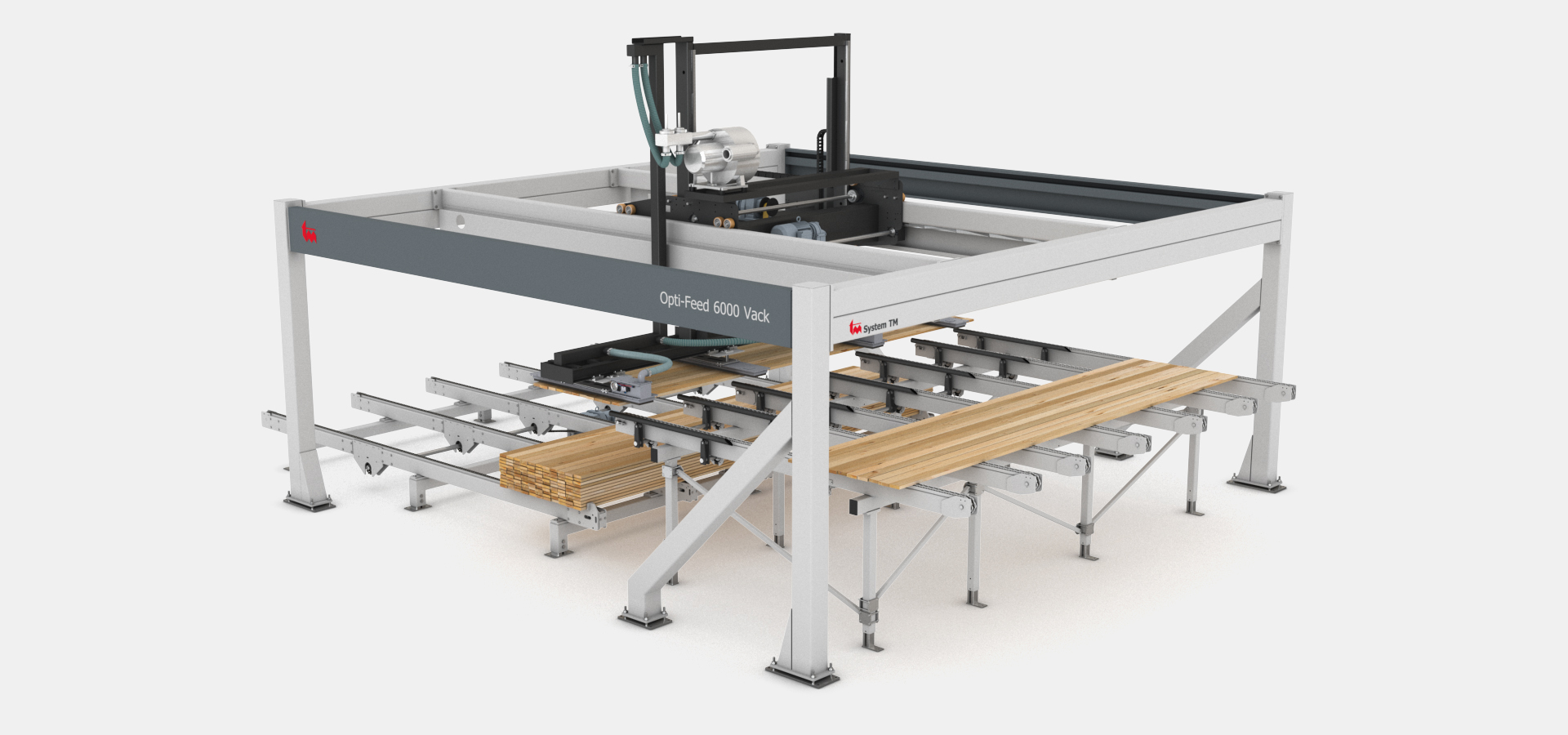

Opti-Feed 6000 Vack is a vacuum de-stacking unit which is able to feed complete or partial layers of workpieces in the correct order into different main machines such as cross-cut saws, moulding machines, double end tenoners, resaws and sanding machines.

Opti-Feed 6000 Vack is suitable for feeding long workpieces from 1,200 – 6,000 mm (4’- 20’) at a capacity of 4 layers per minute, by random or uniform lengths and widths.

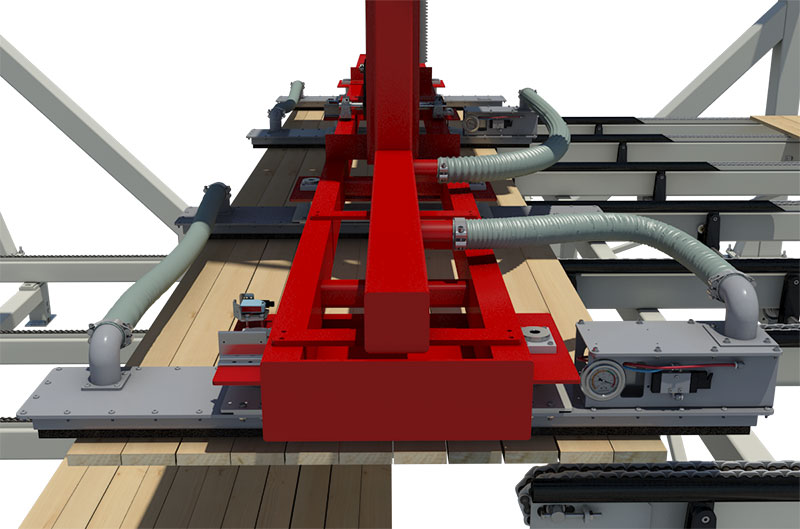

The vacuum heads are equipped with check valve technology, which automatically recognizes and closes the check valves in areas without workpieces. This ensure very secure handling and lifting of all layers, random lengths and widths without any adjustment of the vacuum heads.

By a modular design the Opti-Feed 6000 Vack de-stacking unit is suspended from a portal, enabling de-stacking of layers from packs standing directly on the floor without production stop of the main machinery.

With System TM’s Opti-Feed 6000 Vack we are able to advise and supply you with the right solution to fulfill your specific requirements and demands, to obtain a more efficient and profitable production.

- De-stacking from multiple destinations

- De-stacking to multiple destinations

- Releases labor from hard and repetitive work

- Capacity increase of the main machines

- Gentle handling without damaging workpieces or layers

- Minimum space requirement

- Feeding of random lengths and Widths

- Automatic removal of stabilizing or drying sticks

- Stick collector

- Automatic pack transport

- Receiving chain conveyor

- Customized features upon request