Furniture manufacturer

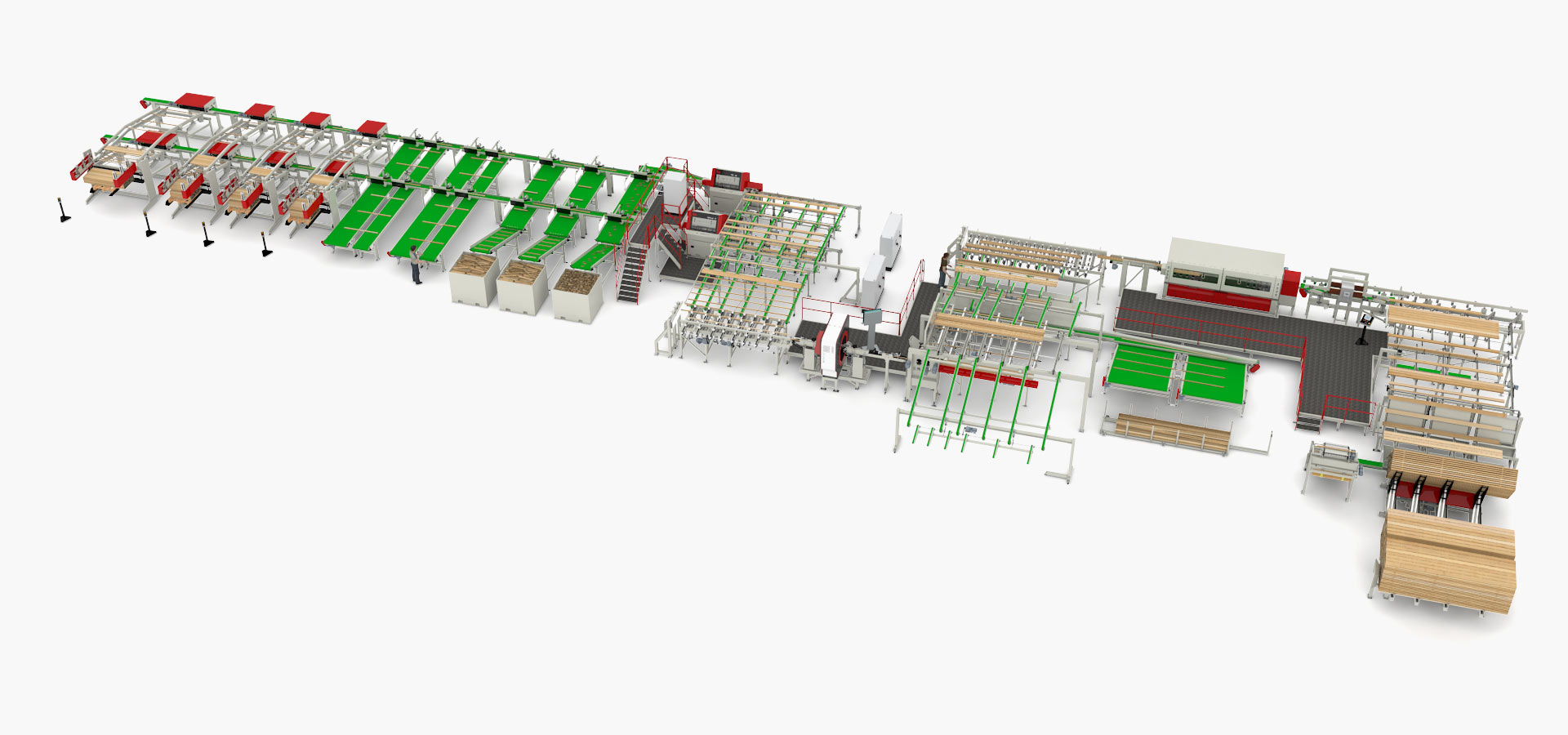

The customized system solutions are individually designed and manufactured, always considering the customer’s production and main machines.This gives our customers a highly integrated line that is fully optimized regarding facilities, production, capacities, yield, and staff resources.

Furniture manufacturer

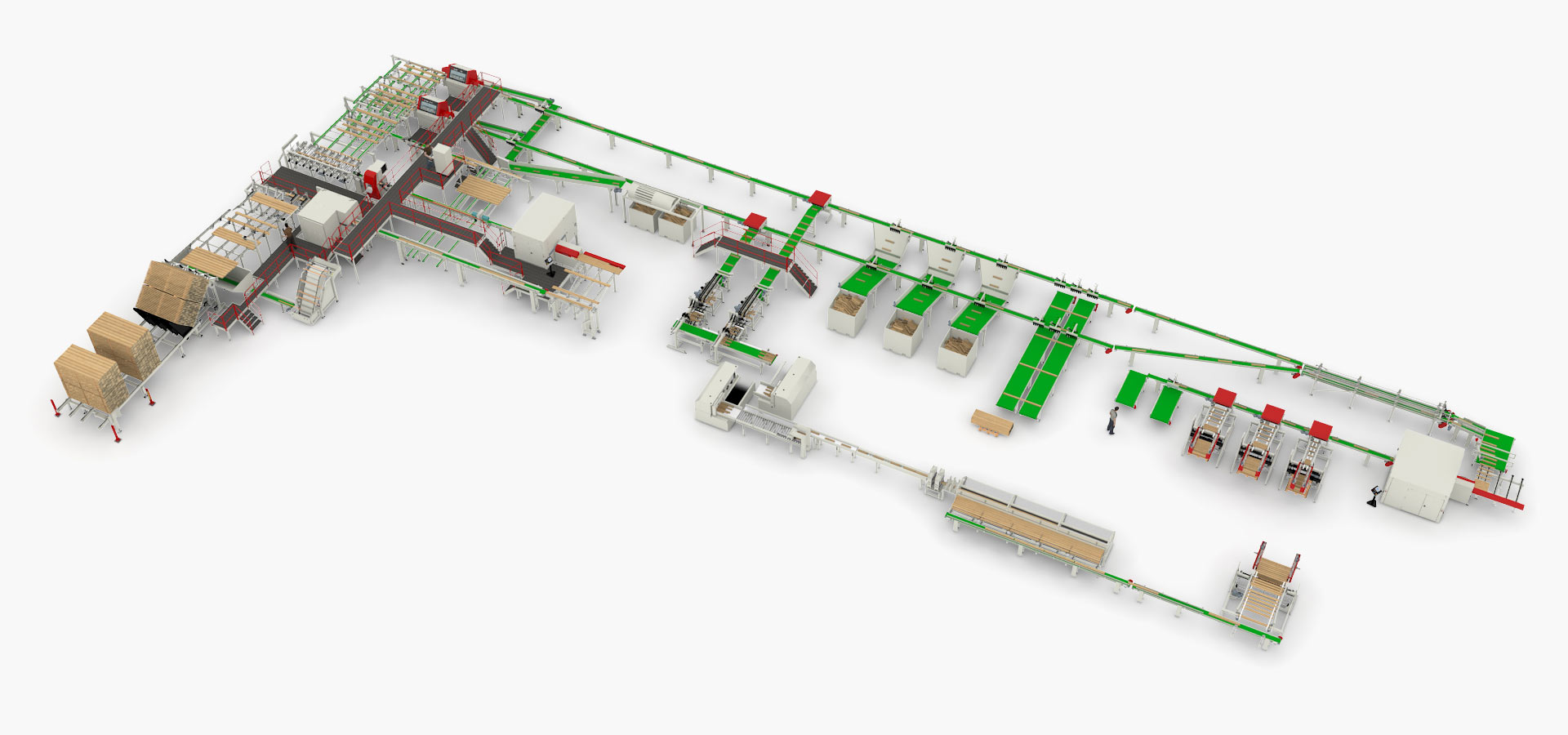

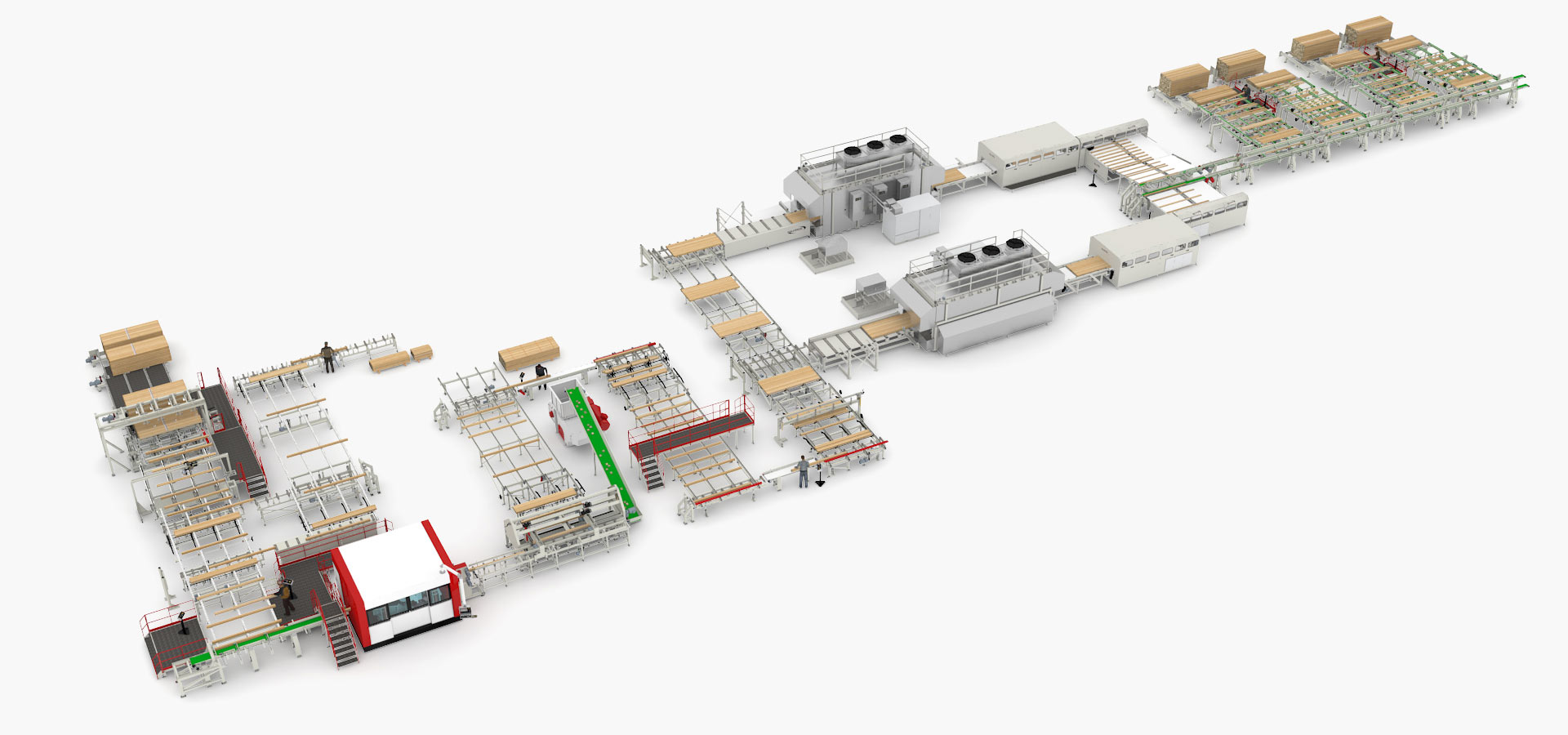

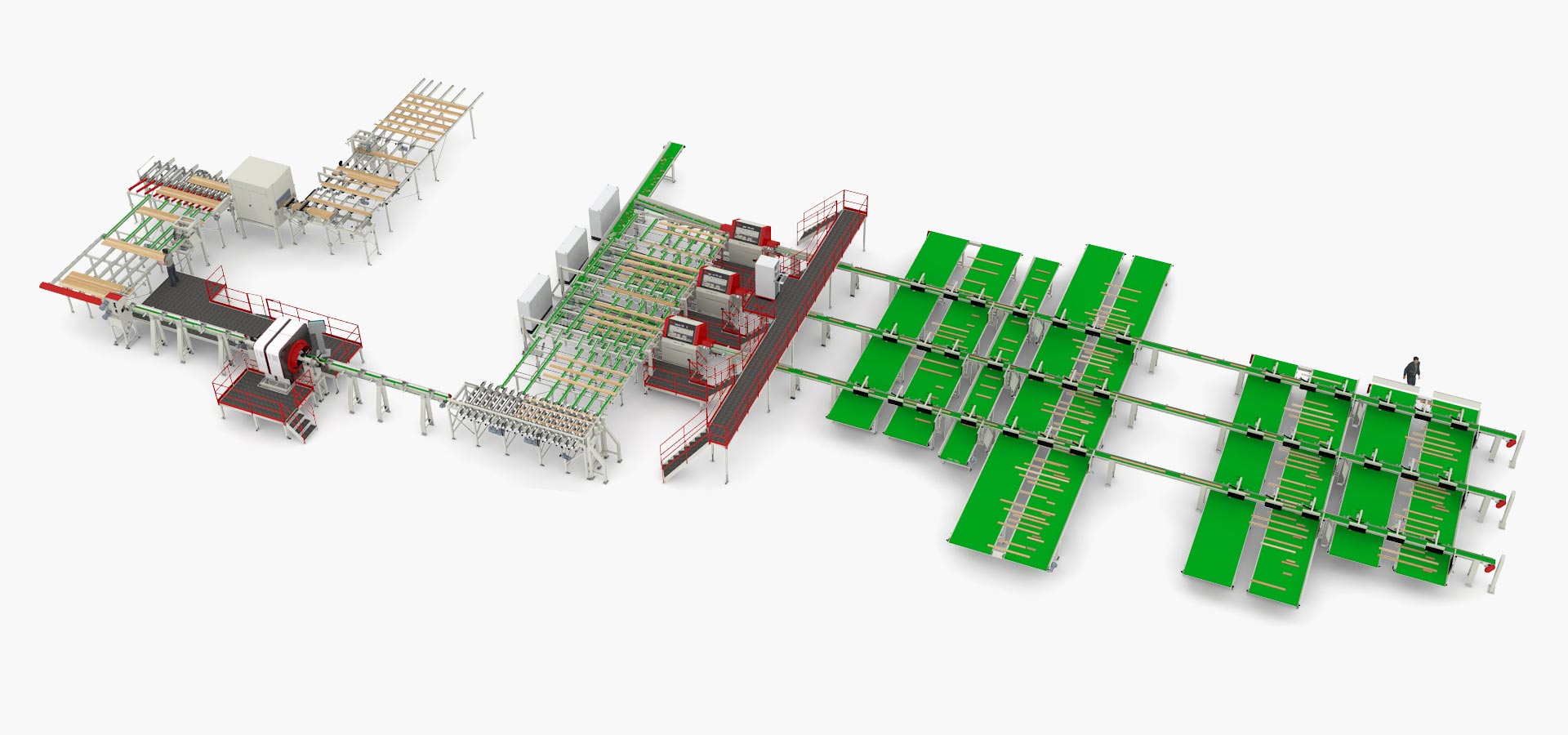

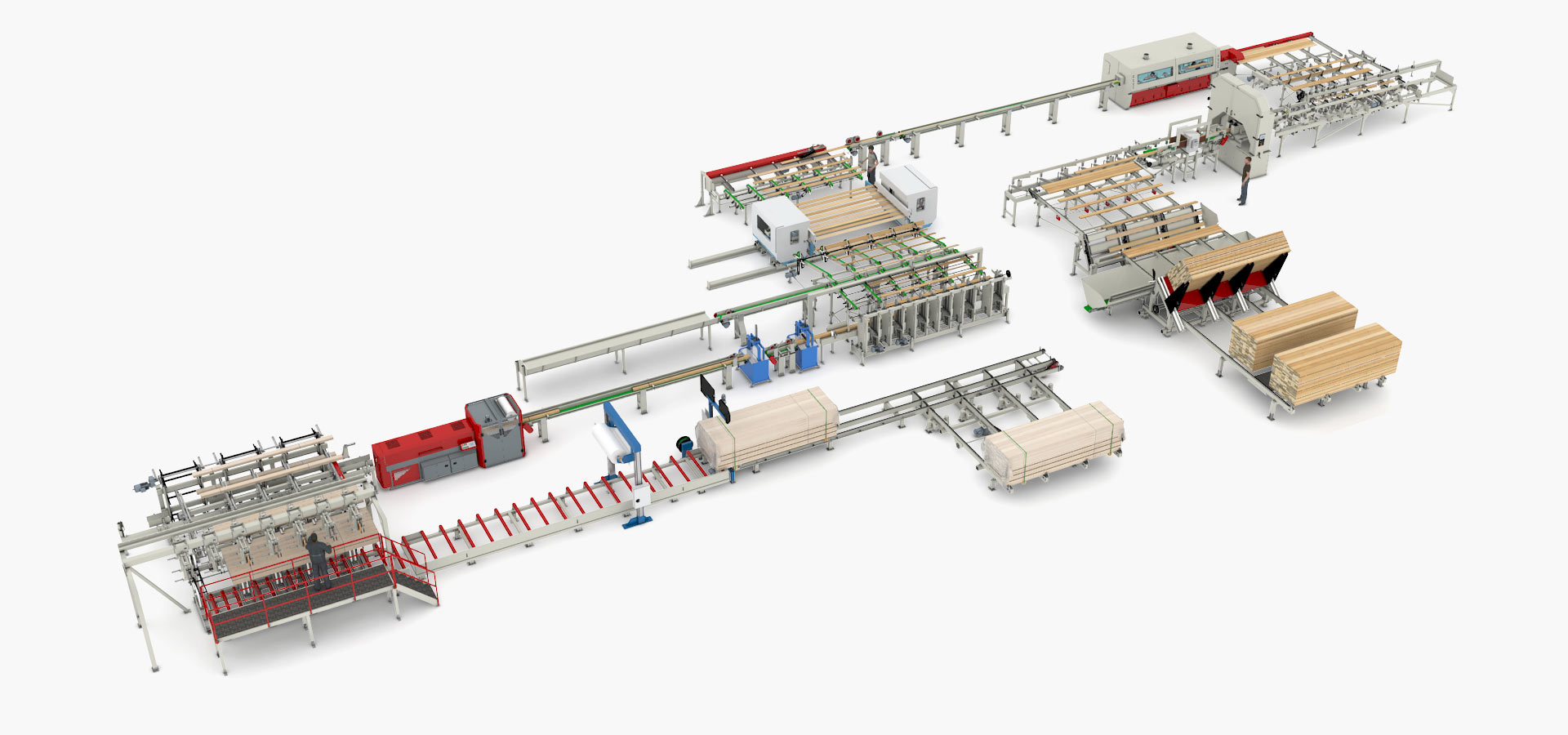

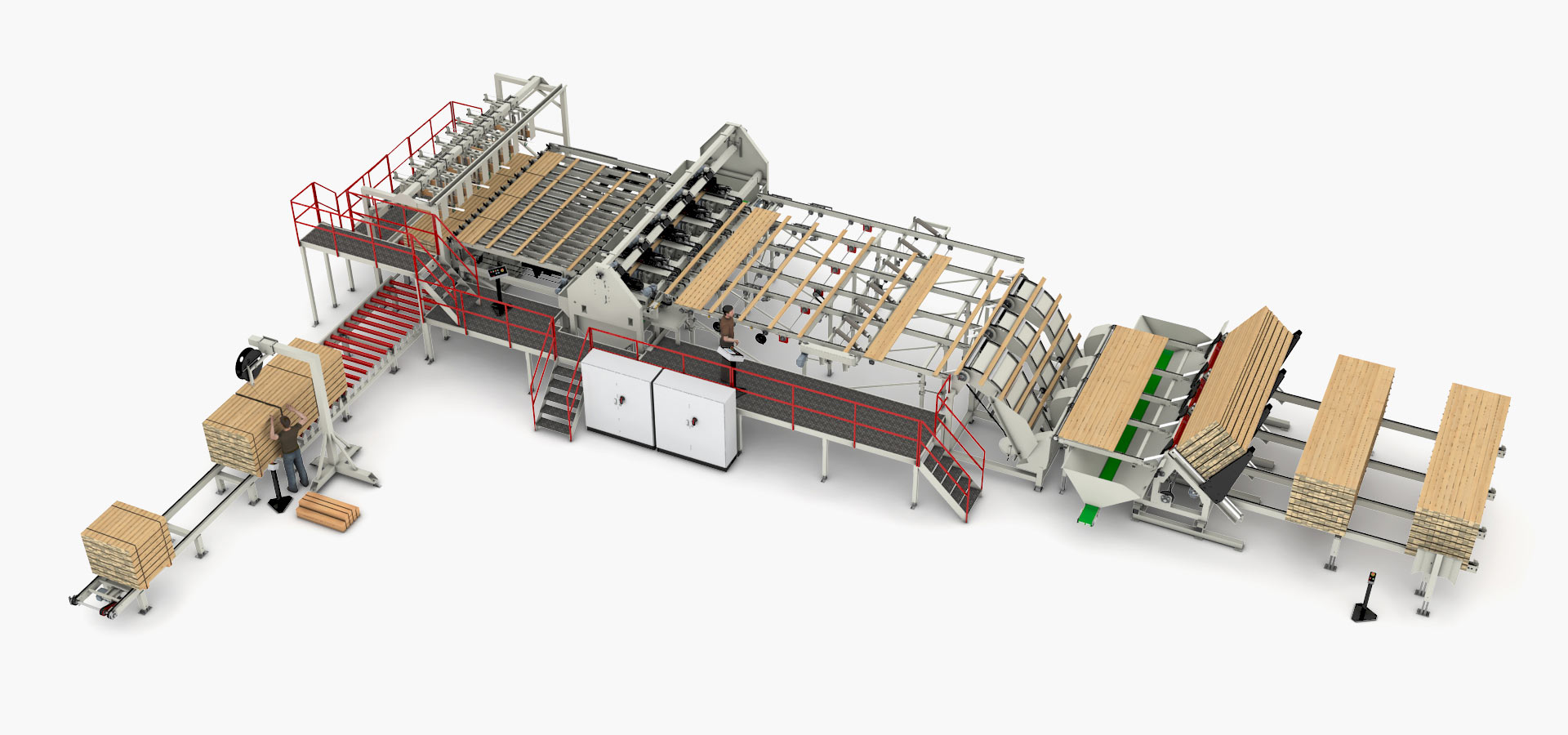

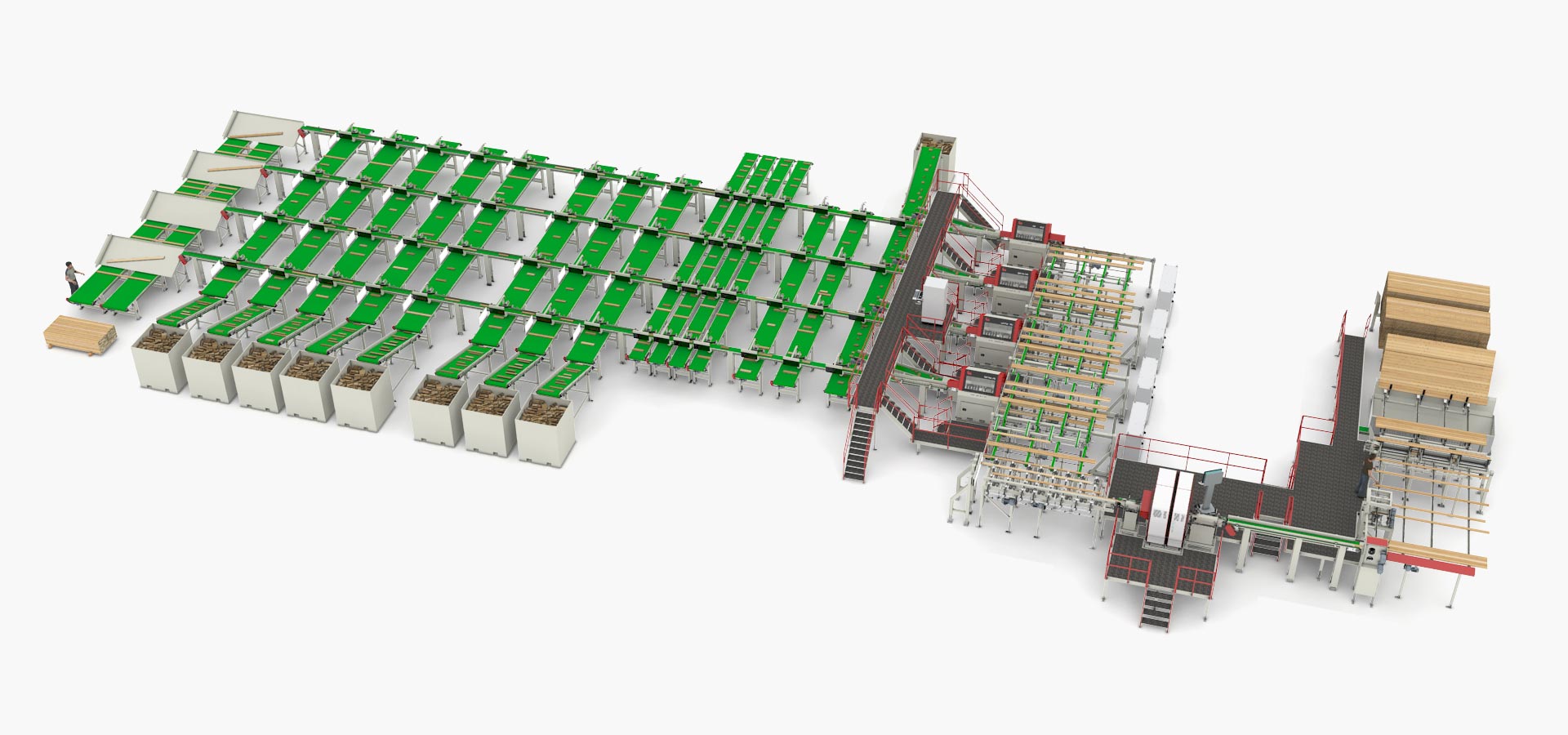

This Opti-Solution is an optimizing cross-cut line consisting of an automatic infeed system model Opti-Feed 6000. The infeed system feeds the raw material to a moulding machine, that splits the workpieces into lamellas. After the moulder, the lamellas are automatically singulated and transported to a Microtec Goldeneye 501 scanner, for detection of defects and quality.

Through a queue control system, the workpieces are then transported to two optimizing cross-cut saws model Opti-Kap 5003, that cuts the workpieces into furniture components.

After cross-cutting, the components are sorted for either finger joint components or fixed lengths, stacked manually or automatically by four stacking machines model Opti-Stack 3000.

System TM’s lines are characterized by:

- System TM’s optimizing software – the only software available optimizing on both wood resources and the overall line capacity.

- System TM’s individual design. The lines are individually designed and manufactured, always considering the customer’s production and main machines. This ensures our customers high-performance materials handling, and 100% workpiece control throughout the line.

- Complete hard- and software integration between all functions of the line.

- The best return on investment.

- Low labor costs and optimal utilization of the wood, ensure our customers to stay competitive in the global market.

- Higher efficiency for all main machines.

- Automatic production changeover from one central computer.