October 21, 2013

Holzindustrie Schweighofer invests in optimizing sorting line for production facility in Romania

After having developed and built several production facilities in Romania, it was time for Holzindustrie Schweighofer to invest in new high quality equipment. System TM designed and presented them with a sorting solution fulfilling their demands and expectations.

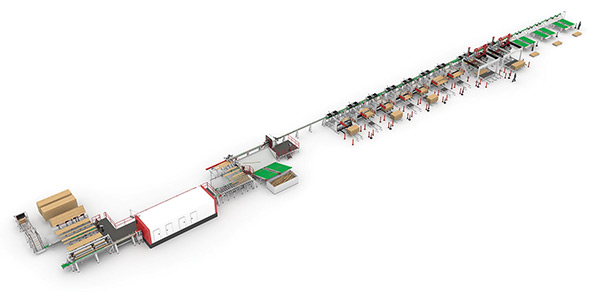

The sorting line from System TM

The sorting line delivered to Schweighofer is a high-speed sorting line that produces lamellas for edge glued panels. It consists of an Opti-Feed 6000 infeed solution that automatically transports the lamellas to a multiple cross-cut saw model MK3, capable of splitting them into two lengths. After splitting, the lamellas are transported through a moulder where the lamellas are split again. The sorting line is designed so that it is possible to run with both different lengths and thickness of the lamellas, hence gaining much more flexibility and utilization of the wood.

After the moulder the lamellas are stress graded, and the weak lamellas are sorted as waste. The other lamellas are then fed into a high-speed infeed before the scanner. The scanner is a MiCROTEC GOLDENEYE 501 scanner and is the fastest within this industry. The scanner is capable of scanning the lamellas according to an unlimited number of qualities, which gives Schweighofer the possibility to run a much varied production. Because of the many opportunities within quality sorting, the line consists of:

- Opti-Feed 6000 infeed system

- Multi head cross-cut saw for single piece feeding MK3

- Moulding machine

- Seven automated stacking systems model Opti-Stack 3000

- MiCROTEC GOLDENEYE 501

- Two vacuum stacking systems model Opti-Stack 6000

- Two tables for manual stacking.

Professional co-operation

Schweighofer is a company where quality and innovative solutions are part of their history and they have many years of experience within the business. The entire process has been handled with the upmost professionalism, and System TM is very proud to have been chosen to deliver this optimizing sorting line to Schweighofer.