December 17, 2018

How automation gives OTC an edge over competitors

By Malene Bou Zeid

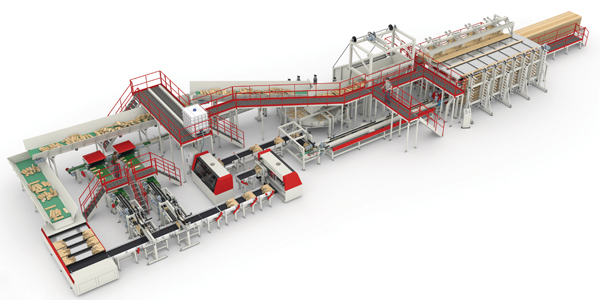

As raw material prices increase and international market competition intensifies, OTC Timber continuously invests in new technology to improve yield and productivity. This time, OTC invested in an Opti-Joint V-8 finger jointing line to achieve competitive advantage.

Based in Otorohanga, New Zealand, OTC Timber processes 100% plantation grown New Zealand Radiata pine to produce a wide range of standard and custom mouldings and finishings for interior and exterior use.

As the demand for wood fiber (logs and sawn boards) is currently increasing, New Zealand manufacturers face increasing competition for raw material and finished goods in end markets. As a result, utilizing the best technology and automation solutions available is a prerequisite to stay competitive. Competition from products other than wood also pose a threat. If OTC’s products don’t compete with other products such as steel, aluminum, concrete, and composites, OTC’s products run the risk of being substituted. Therefore, OTC must stay competitive with other solutions that customers may choose from. Also, the capability to perform versatile manufacturing is important for OTC to meet customer demands for short lead times.

“The new finger jointing line is an important part of OTC’s strategy. Using the System TM finger jointing line investment, OTC must apply automation better than competitors and ensure it fits with the company’s key competencies.”

– Nigel Wilshier, Managing Director of OTC

OTC’s former finger jointer presented a few challenges

OTC’s finger jointing machine was nearing the end of its useful life, underperforming in terms of capacity, and keeping OTC from meeting business growth. OTC’s finger jointer posed safety risks, as it was difficult for operators to keep up with, and required a lot of heavy manual work to position blocks into batches in order to feed the machine.

What makes a repeat customer like OTC come back?

Having known System TM for a long time and having previously invested in System TM machinery, OTC knew exactly who to contact for a finger jointing line with high capacity, high efficiency, more automation, improved safety, excellent quality of finished products, a robust design, and a long life.

Exceeding target productivity levels

OTC’s finger jointing line has helped boost productivity to a great extent. Although OTC’s production target was to increase production 60% more than the old line, OTC has already achieved 92% of the target in the last 3 months. As a result, the underlying targets for the finger jointing line is to increase production significantly, improve operation safety, enhance product quality, and eventually be able to operate with less labor when processing some of OTC’s regularly processed products. OTC is currently operating at over 90% of the production target, safety is better, product quality is better, labor numbers are the same (with a lot higher production) and the company sees future improvement opportunities as the line is enhanced.

Manufacturing more for less to minimize unit costs

Today, unit costs are lower at OTC, as the company produces higher volumes with the new finger jointing line compared to the old line results.

Turning waste into profits

Gone are the days of revenue loss due to wood waste. Thanks to the Opti-Joint V-8 line, OTC has reduced waste, breakage and rework to a great extent. As a result, the finger jointing line has contributed to increased revenue, as OTC now also buys less supplementary raw material and manufactures more of its own.

Automation gives OTC an edge over competitors

Using the best technology and automation is a key enabler to improving results. For OTC to compete in international markets, the company must be agile, quick to adapt and change, responsive to customers and provide better service as a way to successfully compete.

“The automation of the new finger-jointing line gives us greater ability to use a wide range of employees to operate the machine. From a safety perspective, less wear and tear on the body means the long term health of our employees is enhanced.”

– Nigel Wilshier, Managing Director of OTC