January 8, 2016

Launch of a new horizontal finger jointing machine: Opti-Joint H-200

System TM launches new finger jointing machine Opti-Joint H-200 and expands our current product portfolio

The demands from the solid wood industry for components of a more uniform quality and a more stable product, is increasing. This means that there is a rise in the production of finger jointing workpieces and laminated components. Because of this, System TM has developed and designed a new horizontal finger jointing machine that also matches our existing product portfolio.

The material handling solutions from System TM can automate standalone finger jointing machines with automatic in-feed and stacking standard systems. Furthermore, the finger jointing machines can be integrated into project solutions with a direct flow of workpieces being transported directly from other main machines such as scanning and optimizing cross-cut saws. When connecting the finger jointing machines to scanning and cross-cut lines you minimize the logistics of handling all finger jointed blocks and are able to produce joint workpieces with continuous grain.

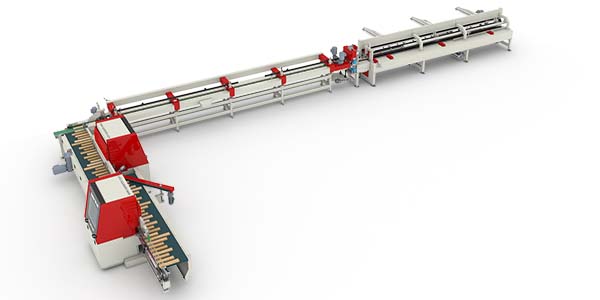

The displayed finger jointing line consists of:

- Automatic workpiece alignment by Spinfeeder, model Opti-Feed 200

- Index feeding unit with variable feed speed for correct and consistent feeding of workpieces

- Lug-loader, model Opti-Feed H-200

- Horizontal finger jointing machine, model Opti-Joint H-200

- Pre alignment and press station

- Adjustable cross-cut unit for trimming and cut to length applications including lumber line deviation

- Stacking machine model Opti-Stack 6000

One of the main focuses behind this development has been to design a horizontal finger joint machine, where the extremely high machine utilization is not affected by existing material handling automation. This is due to our software solutions and ability to integrate and combine different machine modules, but also because of our experience with high-capacity handling of workpieces in a continuous flow. It is important to integrate all equipment surrounding the finger jointing machine to ensure a continuous high capacity throughout each workday.