November 27, 2023

New optimizing cross-cut line expands Cordes’ production capacity in Bremerhaven

By Aislinn Esterle

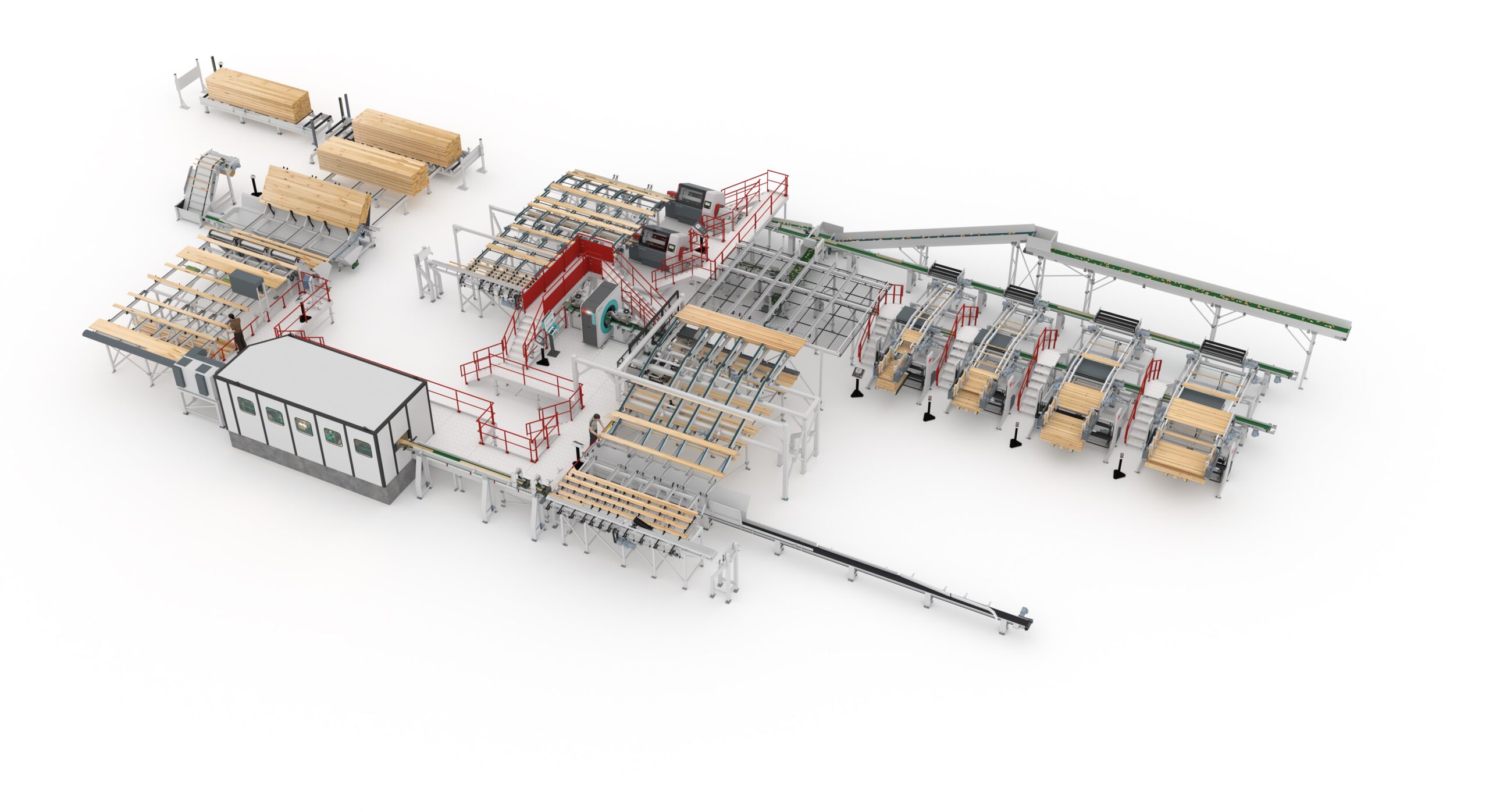

German company Cordes GmbH & Co. KG entrusted System TM to provide a complete cross-cut solution tailored to limited existing space available in their factory.

System TM is looking back on a long history with Cordes, or rather the Cordes family, valued customers who have t rusted us for many years. Area Sales Manager Per Juul Jensen is looking back: “The first line was an Opti-Kap line with an Opti-Kap 2000 and was sold back in 2003 to Bernhard Cordes (father to current managing director, Andreas Cordes) in Bremerhaven.” Following this, two more lines were sold to two Cordes family-owned companies: A band saw line to Krages Holzindustrie GmbH & Co. KG in Hamburg and another band saw line with in-feed and stacking system to Osmo Holz und Color GmbH & Co. KG, located in Warendorf. By then, System TM had built a strong r elationship with the Cordes family, which lead to the next project. A cross-cut line was sold to Lamico B.V. in Winschoten, Nether-lands, to Andreas Cordes. his line would be the paragon for the latest optimizing cross-ut system with MiCROTEC Goldeneye 501, two cross-cut saws type Opti-Kap 5103 and four stackers model Opti-Stack 3000.

The place for all things wood

Cordes GmbH & Co. KG is a provider of planning mill products to customers world-wide, however, the company’s area of expertise is much more complex. Founded in 1980 as an import planing mill by Bernhard Cordes in Bremerhaven, the c ompany q uickly developed into one of the largest suppliers of wood and planing mill products in Germany. Today, they can be seen as a full-range supplier of planed wood, offering a broad v ariety of products ranging from planed timber, solid structural timber (KVH®), DUO+TRIO, glue laminated t imber, timber beams, sawn timber, solid wood p anels, wood-based materials and g arden timber to wood briquettes and pellets. Continuous nvestment in p roduction f acilities – such as the Bremerhaven site, where the new System TM line is also l ocated – ensures, that Cordes can meet high quality standards and fulfill individual customer requirements, always focusing on offering the best possible pro duct at the best possible price.

Invest to make the best

The new grading and cross-cutting system underscores the company’s commitment to keeping its production facilities up to date. This ensures manufacturing of high- quality products, while maximizing raw material u tilization and improving capacity at the same time. Packs of unprocessed wood are first transported and buffered in front of a tilt hoist, where the timber packs are unstacked layer by layer and continue to a separator. From there, they are transferred individually to a subsequent conveyor and buffered before being measured for moisture and cop. Workpieces with too much moisture are automatically rejected and those that need turning are automatically turned.

They then move on to the planer, which has a maximum speed of 120 m/min and offers the possibility of splitting the boards into lamellas or retaining single workpieces. An operator then sorts the parts by visual i nspection and has two options: On the one hand, he can operate two or more arms on the conveyor that can tilt up to facilitate the sorting of workpieces with knots, which then break and are automatically sorted out. On the other hand, it is possible to pull the pieces over the 0-edge so that they can be trimmed with a trimming saw.

Small space and great improvements

This complex, yet compact, solution has one big advantage: a storage hotel. This makes it possible to send workpieces to an external storage area. In other words, if the line stops, the parts can be fed back into the line from the storage hotel. This gives the customer flexibility and capacity, while reducing the risk of production downtime, as the material is available in the storage area to maintain production.

All good parts – either coming directly from the planer or from the storage hotel – then pass through a MiCROTEC Goldeneye 501 quality scanner at up to 300 m/min for optimization. The parts are then collected in a unit and distributed to the two Opti-Kap 5103 saws, one of the fastest cross-cut saws on the market supporting high production volumes.

Here the parts are cut to the correct length and can be turned, if necessary, before being stacked for pickup by one of the line’s four Opti-Stack 3000 stackers. The finished workpieces are then used for the glulam board production.

Trust and experience

We are very proud to count the Cordes family among our long-standing customers. It takes a lot of trust on both sides to maintain such a strong relationship. So much so that Andreas Cordes didn’t come to Denmark to inspect the line in person, says Per J ensen: “He said he trusted our e xperience c ompletely and didn’t see the need to travel to Denmark to test the line.” Every System TM line is built and tested with the customers materials in Denmark before being dismantled, sent and set-up at the customer’s site. We truly appreciate that our customers feel ensured by our know-how and expertise to know that we will always do our best to fulfill their wishes.

“After the final adjustments, we were able to triple our production volume with the new system and significantly increase the yield. In addition, we were able to target new customer groups with specialized sorting andfixedquantities.”

– Andreas Cordes, Managing Director of Cordes GmbH & Co. KG