Auswest Timbers

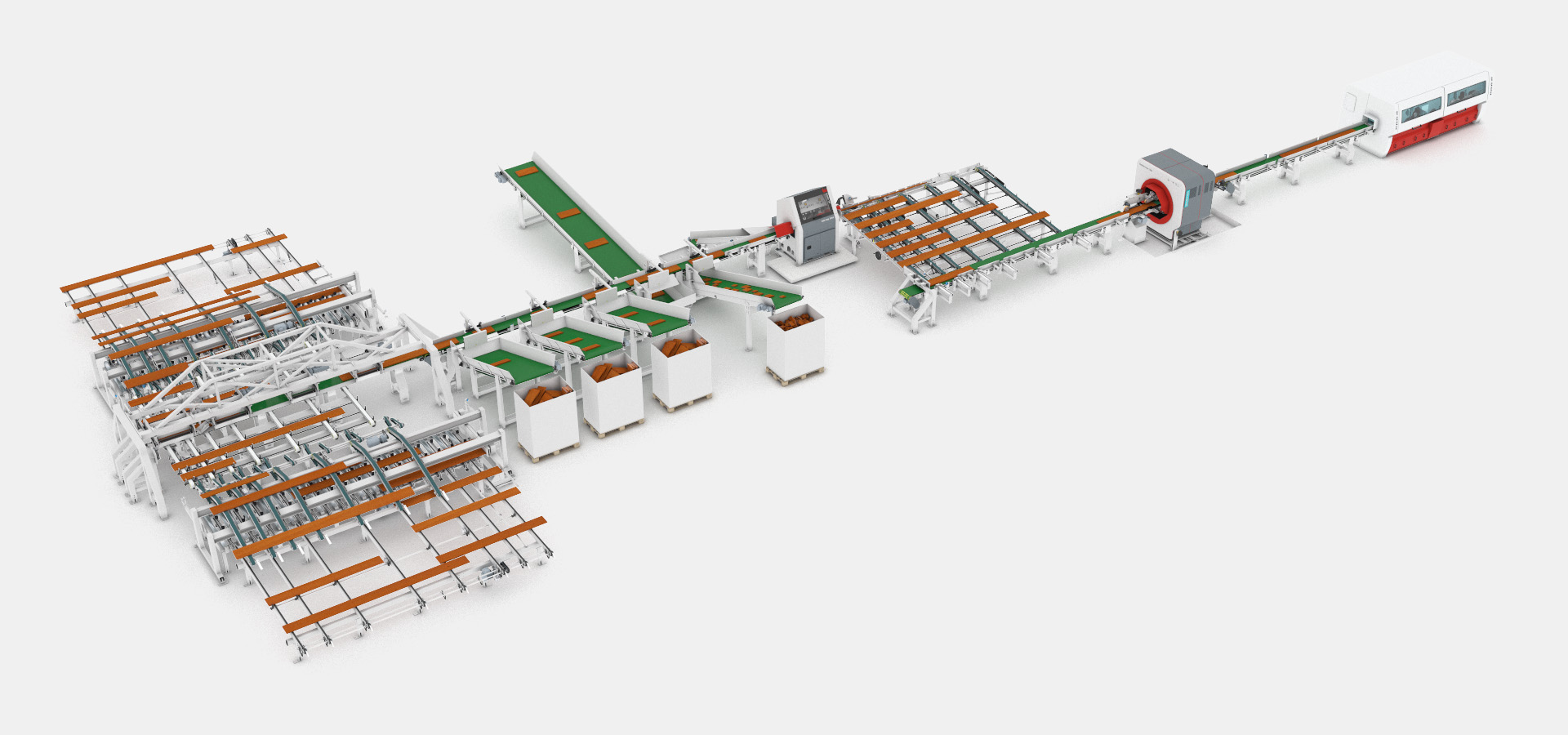

The optimizing cross-cut line

Before the installation of the cross-cut line, the operators at Auswest Timbers manually crayon marked each workpiece for defects before they were cross-cut. With the installation of the Goldeneye 302 scanner it is now possible to automatically quality grade each workpiece. Furthermore, the optimizing cross-cut saw Opti-Kap 4003 cuts the workpieces according to the scanning and optimizing results. After the cross-cut saw, the workpieces are sorted as waste, according to different qualities for finger jointing components. Due to limited space available for the line, System TM developed a sweeper system where workpieces can be transported both left and right can be stacked manually from two positions on each side. This makes it possible to run with four different qualities in each production.

High return on investment

The equipment of System TM and Microtec is very strong and solid, hence capable of handling the hardwood in the production of Auswest Timbers. Installing this solution has resulted in a very high wood utilization with a minimum of waste, leading to a fast return on investment.

The solution consists of: