Lauzon Hardwood Flooring

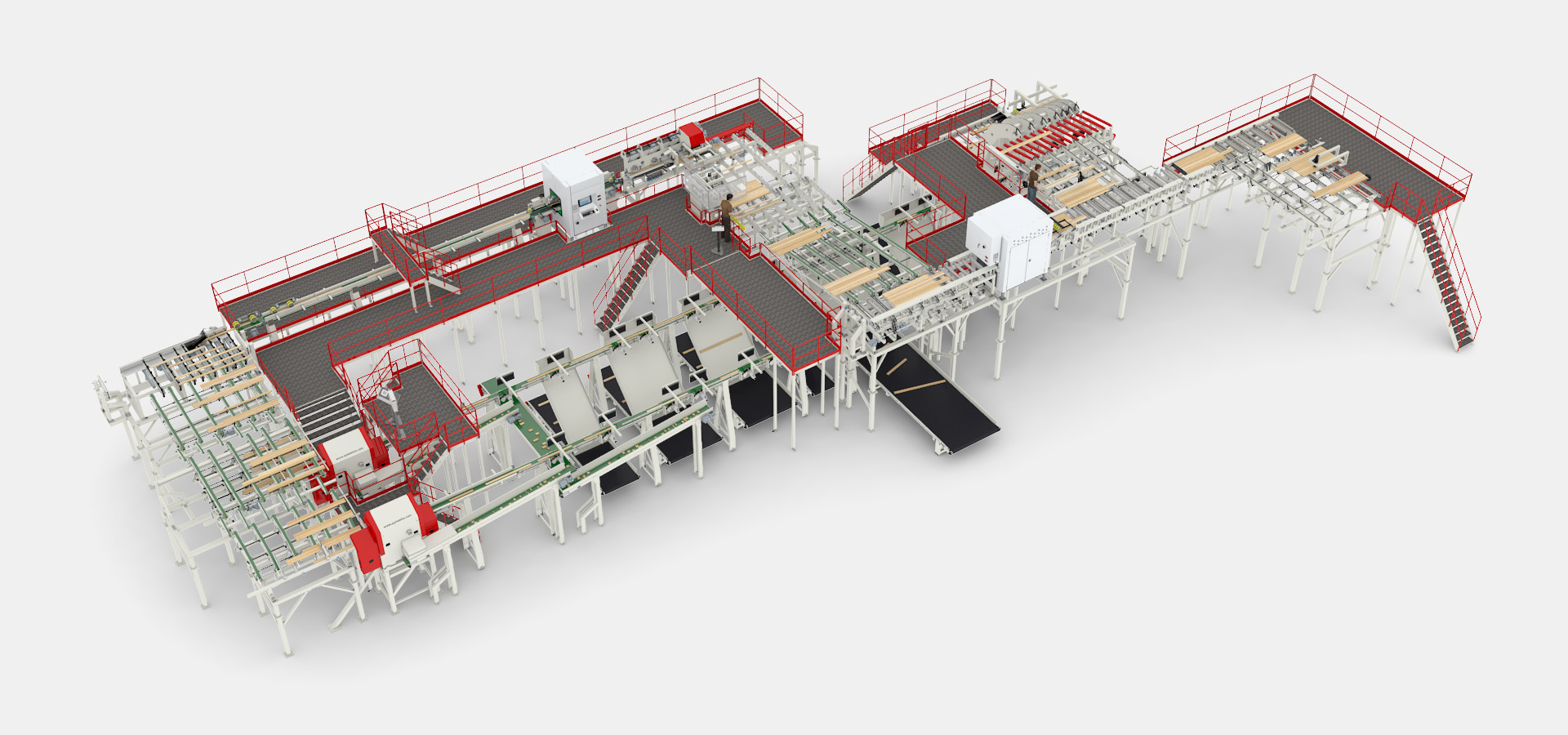

A highly advanced optimizing cross-cut line

Lauzon Hardwood Flooring’s line consists of a batch planer, a scanner and two optimizing cross-cut saws, Opti-Kap 5003, linked together by material handling systems.

At first, workpieces are fed into the line by two feeding systems, in which each feeding system creates batches of workpieces. These are fed into a self-centering batch planer, and then transported to a scanning unit. A trim saw, placed in between the planer and scanner, trims workpieces with spear ends and/or curved workpieces. Then, a high-speed scanner feeder feeds workpieces into a scanner. After scanning takes place, workpieces enter a buffer system that distributes workpieces to two Opti-Kap 5003 saws. Finally, workpieces are managed by sorting belts which sort workpieces out and thus, prepare them for the subsequent processes.

Customization is our strength

Throughout the design and development of this System TM cross-cut line, countless drawings were outlined to bring forth a system solution of maximum capacity and lumber utilization.

The construction of this line is rather unique, as it is tailored to fit with Lauzon Hardwood Flooring’s existing machinery and facilities. Thus, installing System TM’s line and integrating this with Lauzon Hardwood Flooring’s existing machinery was a delicate task. However, System TM showed consideration for business continuity by doing its utmost to minimize manufacturing downtime through-out the installation process.

The solution consists of: