Meble Negro

The optimizing cross-cut line

Due to rapid business growth and rising production requirements, Meble Negro embraces cutting-edge technology to maintain a strong market position.

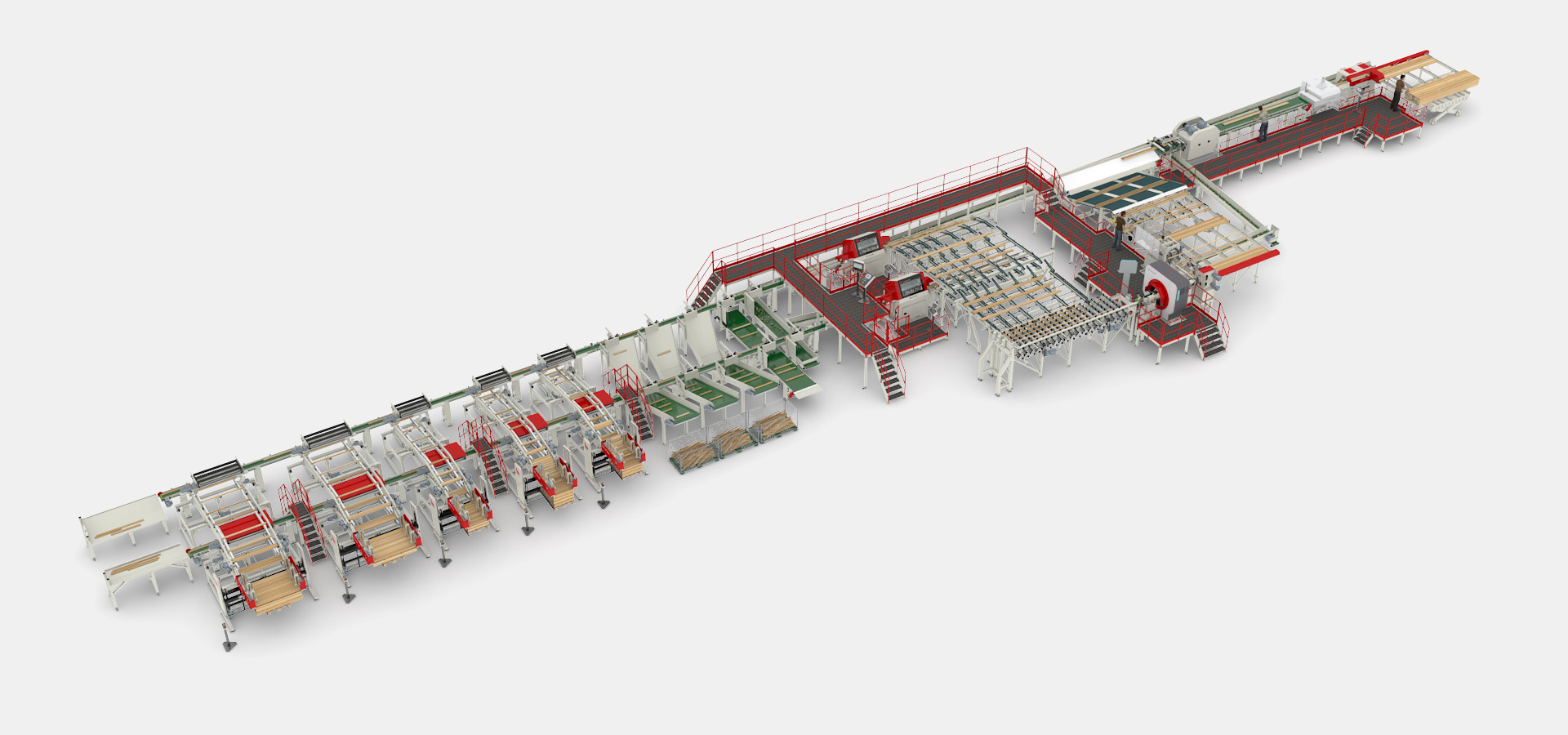

System TM’s solution consists of an Opti-Feed 6000, a ripsaw and planer, a Microtec Goldeneye 501 scanner, two optimizing cross-cut saws, Opti-Kap 5003 and five Opti-Stack 3000 stacking machines.

Initially, an Opti-Feed 6000 feeds workpieces straight into a ripsaw/planer solution which splits and calibrates workpieces on all four sides. This enhances the scan results of workpieces once they arrive at the Microtec Goldeneye 501 scanner further on. Prior to scanning, workpieces are sorted out to eliminate those of poor quality. A trim saw, placed before the scanner, trims workpieces with spear ends and/or curved workpieces. This improves the quality of workpieces before they enter the Microtec Goldeneye 501 scanner. After scanning takes place, workpieces are collected in batches and transported to two optimizing cross-cut saws, Opti-Kap 5003. Workpieces are cut by making the most effective use of raw wood in relation to what the customer wishes to produce. After cross-cutting, workpieces are sorted out by sorting lines – a combination of four belts for manual stacking of finger-jointing lengths and five Opti-Stack 3000 machines for automatic stacking of fixed lengths.

The solution consists of:

- Two optimizing cross-cut saws model Opti-Kap 5003

- Microtec Goldeneye 501 scanner

- Five automated stacking systems model Opti-Stack 3000