Millette Doors

An intelligent multipurpose system

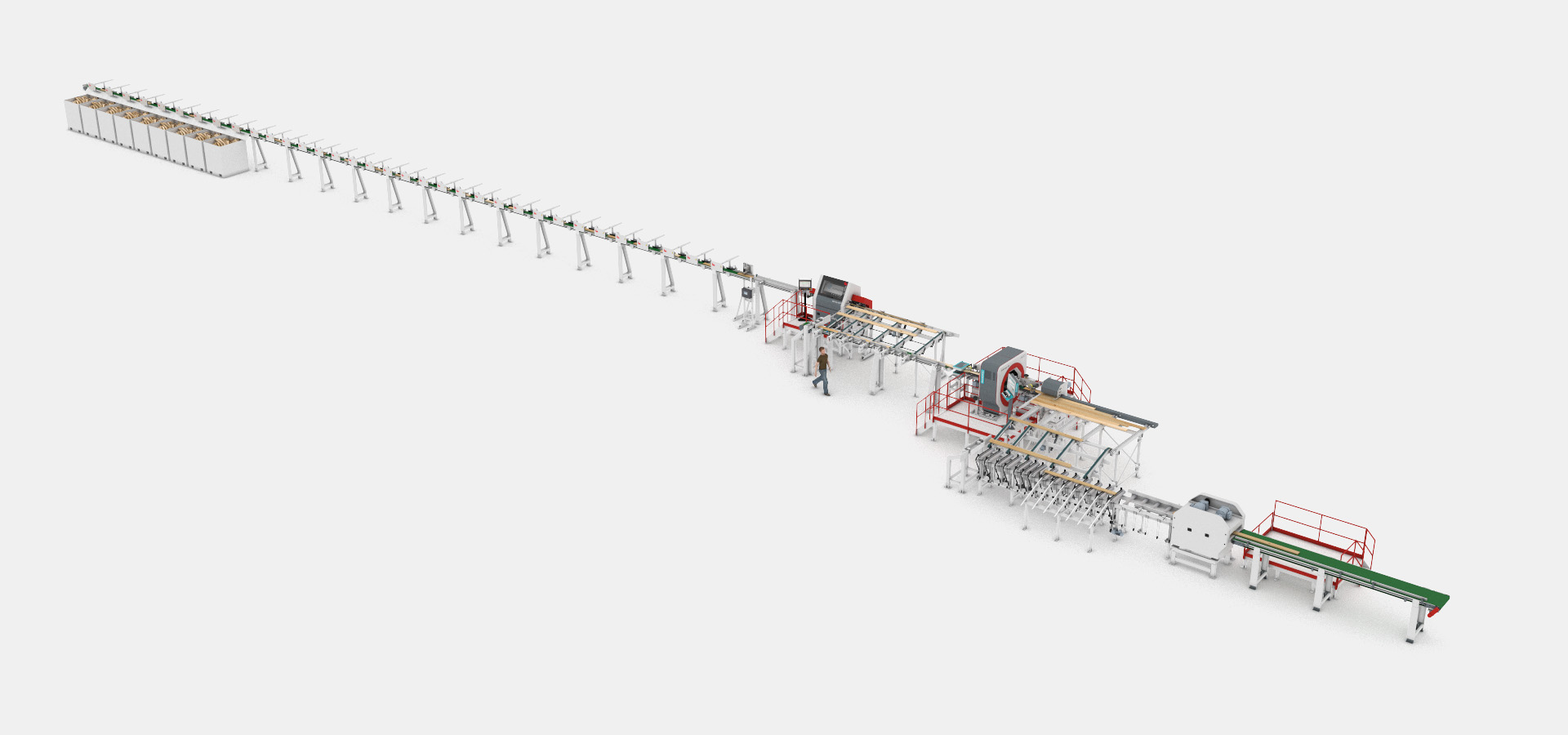

The Opti-Kap 5003 cross-cut line is a replacement of Milette Doors’ former cross-cut line and its manual crayon marking system. Not only does this new cross-cut line significantly increase production capacity, but what is truly noteworthy about this multifunction system is its two wood processing options within a single system. Furthermore, it provides exceptional utilization of timber resources and prevents the formation of large volumes of wood offcuts. All in all, Milette Doors has achieved cost savings by purchasing a single system that performs multiple functions rather than purchasing multiple machines. In addition, savings have been made on material costs due to better wood utilization.

The first system option helps process wood in preparation for finger-jointing. This process begins just after Milette Doors’ existing planer, in which a Microtec scanner, Goldeneye 301, scans and defect-analyzes long wood boards. Then, wood is transported to an optimizing cross-cut saw Opti-Kap 5003 saw, in which workpieces are cut in accordance with the specifications of Milette Doors. Next, an ink printer handles workpieces using distinctive capabilities that have been designed by System TM for the first time.

Then, workpieces are transported to a sorting line, from which they are distributed into bins or manual stacking stations. Finally, once distribution is complete, workpieces are transported to a remote finger-jointing system.

The second option offered by this system is intended for products that don’t require grading, as these products only need to be surfaced by the planer and stacked as they are. Thus, this option provides the possibility to bypass the scanner and everything that follows, allowing workpieces to move directly to the manual stacking area.

The solution consists of:

- Optimizing cross-cut saws model Opti-Kap 5003

- Microtec Goldeneye 301 scanner