UAB Multimeda

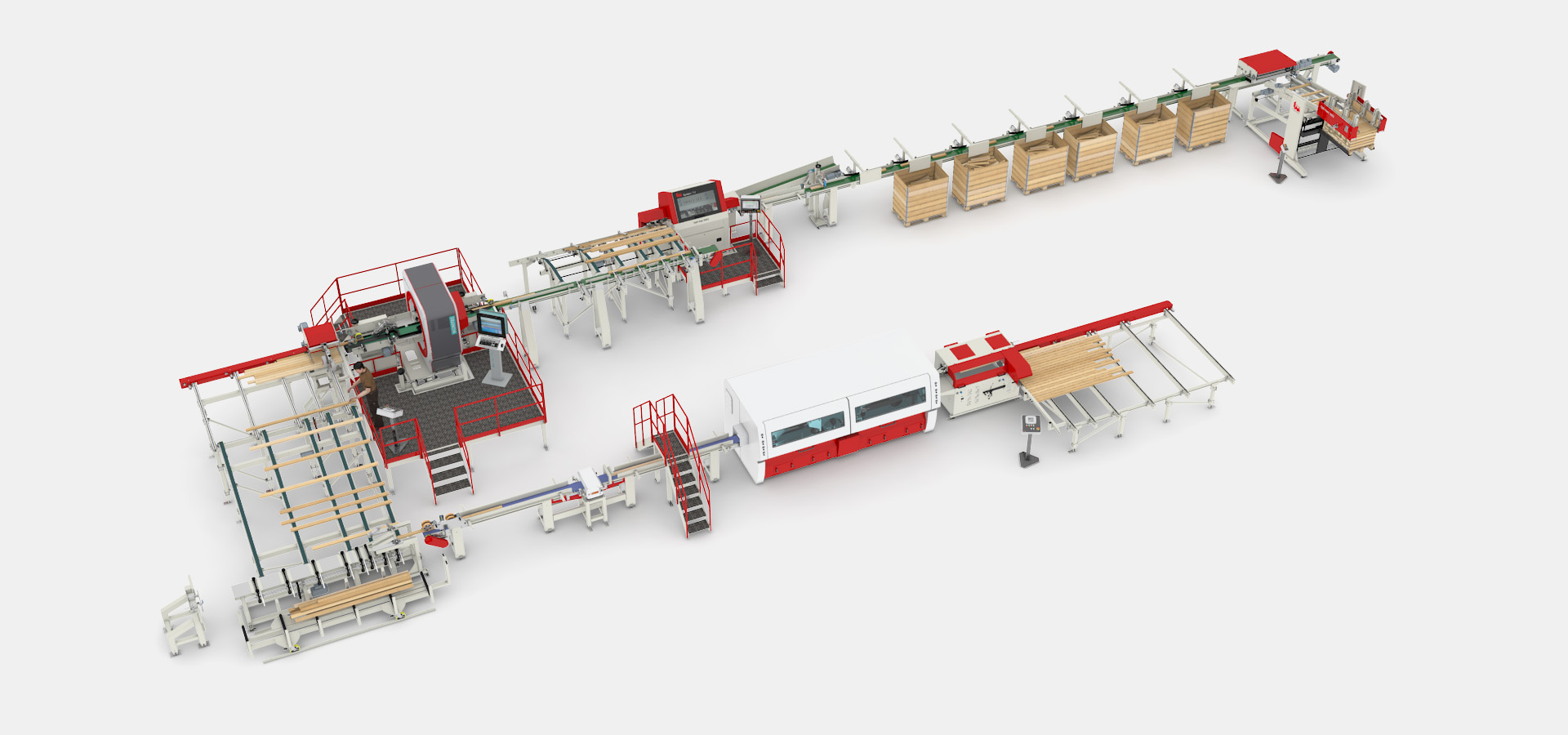

The Opti-Kap 5003 line

The intelligent management software incorporated in System TM’s line minimizes down time by automatically resolving errors and by reducing the need for operator intervention and presence. AB Multimeda’ s Opti-Kap 5003-line investment serves as a significant step toward achieving workpiece quality and uniformity improvement due to the impeccable accuracy of the Opti-Kap 5003 saw.

The initial stage of the Opti-Kap 5003 line is defined as the moulding of workpieces. Once workpieces have been processed by the moulder, they are measured by a moisture meter placed in line with the moulder. This device detects and sorts out workpieces with moisture contents above moisture content limits. Workpieces that adhere to moisture content limits are eventually carried onto a Microtec Goldeneye 301 scanner for the identification of hardwood abnormalities and defects. Next, the Opti-Kap 5003 saw optimizes and cuts workpieces into components by making the most effective use of raw wood. Finally, workpieces are carried out to sorting belt conveyors in which they are categorized according to wood qualities, finger-jointing and fixed lengths.

The solution consists of:

- Optimizing cross-cut saws model Opti-Kap 5003

- Microtec Goldeneye 301 scanner