August 29, 2018

The power of reconnecting with old business contacts: how dormant ties can surprise you

By Malene Bou Zeid

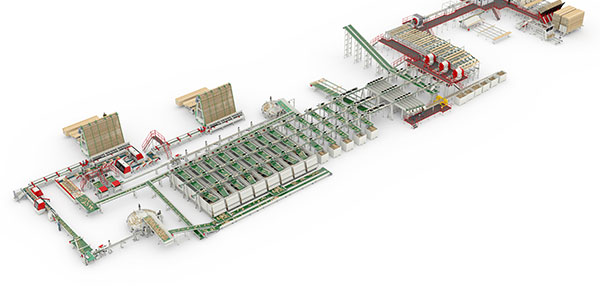

After deciding to upgrade its production machinery, New Zealand-based Niagara Sawmilling reconnected with System TM, an old business contact that Niagara Sawmilling had lost touch with for ten years. Eventually, Niagara opted for technological edge by investing in an extensive System TM cross-cut and finger-jointing line.

Most of us have been there. Sometimes relationships, or in this case, business connections, are disrupted for various reasons without having fully explored their potential. When Ross Richardson, Managing Director of Niagara Sawmilling, decided to upgrade his factory’s equipment due to growing market demand, his thoughts turned to System TM and how he never got to explore how System TM could maximize his production. Although Niagara Sawmilling and System TM had lost touch for ten years, fate would have it that they would be crossing paths again.

After reconnecting with System TM and receiving a project proposal on a cross-cut and finger-jointing line, Niagara visited South America together with System TM’s dealer from down under, Southern Cross Engineering, to see some of System TM’s similar customer reference lines in South America. Soon, Niagara placed an order on a fully integrated System TM line featuring three optimizing Opti-Kap 5103 cross-cut saws and two finger jointing machines – a horizontal Opti-Joint H-200 and a vertical Opti-Joint V-8.

A world-class leader in its field

With 80 years of sawmilling in New Zealand, Niagara operates with the latest technology in sawmilling, kiln drying, treatment, finger jointing, laminating and precision-profiling. Niagara supplies national and international markets with a selection of treated outdoor timber products for building or manufacturing purposes.

Niagara’s strategy = more money in the pocket

The true cost of waste is not simply the cost of discarded materials, it also encompasses inefficient use of raw materials. Niagara puts money in its pocket by employing an effective waste and resource management strategy focusing on sustainable plantation-grown radiata pine and whole-tree utilization. Reject wood is chipped, creating eco-friendly woodfuel for new low-emission boilers. Bark and sawdust are blended with peat to produce composts and mulch. Finally, shavings and sawdust are used to generate energy to run Niagara’s kilns. As a result, Niagara profits both from the economic and environmental benefits of waste reduction.

An extensive line with so much to offer

Initially, package-feeding occurs using a tilt hoist that places two packs on top of each other. Then, workpieces are fed at up to 60 workpieces/minute into a 250-meter Ledinek planer with 4 spindles. Next, workpieces are examined by a MiCROTEC Curvescan deformity scanner that measures bow, twist and crook. The MiCROTEC Curvescan scanner also includes a camera that identifies the wood pith of workpieces. Then, a moisture meter determines the moisture content of workpieces before they are scanned on all four sides by a MiCROTEC Goldeneye 502 scanner featuring an X-ray unit. The scanner data is transferred to an optimizing software program that calculates best cutting position. This data is used by three Opti-Kap 5103 cross-cut saws that follow. As workpieces enter the Opti-Kap 5103 cross-cut saws, the optimizing software program instructs the cross-cut saws how to cut workpieces with maximum wood utilization.

Workpieces exit the cross-cut saws onto three sorting belt conveyors where workpieces are sorted into three classifications: re-rip blocks, finger jointing blocks, and long fixed lengths. Then, all workpieces are distributed according to their various lengths and qualities into the three above-mentioned classifications. Workpieces are either stored in bins, on walking floor bins or on accumulation belts, after which they move straight onto manual stacking or a re-rip machine.

The finger-jointing workpieces stored on the walking floors can automatically be transported by an automatic belt-transporting system to either one of the finger jointing machines, Opti-Joint H-200 or Opti-Joint V-8. The rest of the finger-jointing workpieces which are stored in bins or processed by the re-rip machine can be fed into the two finger jointing machines, Opti-Joint H-200 or Opti-Joint V-8, by a forklift.

The horizontal finger jointing process

System TM’s horizontal finger jointer, the Opti-Joint H-200, processes 200 workpieces/minute. Initially, workpieces enter a spin feeder. Then, two shapers mill, glue and prepare workpieces for the horizontal finger jointing process. Next, a hydraulic press unit presses the workpieces together and forms lengths of 7.2 meters. Once the horizontal finger jointing process is complete, workpieces move onto a large drying tower to dry and harden. If necessary, workpieces can be cut into three pieces using a multiple cross-cut saw, before they are stacked by an Opti-Stack 6000 stacker, packed and transported to subsequent processes.

The vertical finger jointing process

Many of the same mechanisms apply when workpieces are vertically finger jointed by the Opti-Joint V-8 finger jointer. From a spin-feeder, workpieces move along a long buffer belt conveyor onto two sweepers. Then, workpieces move onto two batch-feeders that create batches with widths of 600 mm. Next, batches move onto two shapers that mill, glue and prepare workpieces for the vertical finger jointing process. Then, a hydraulic press unit presses the workpieces together and forms lengths of 7.2 meters. Once the vertical finger jointing process is complete, workpieces move onto a large drying tower to dry and harden. If necessary, workpieces can be cut into three pieces using a multiple cross-cut saw, before they are stacked by an Opti-Stack 6000 stacker, packed and transported to subsequent processes.

From defect to perfect in one system

Designed with high multifunctionality and flexibility, this line encompasses many production processes within one single system. From start to finish, the line takes in raw material and produces two types of finished, flawless, finger-jointed products (horizontal and vertical). As a result, the multifunctionality of this line manifests itself in its flexibility to produce both types of finger joints simultaneously.

Just like all System TM machinery, optimization of staff and wood resources is the driving concept behind this line, which ultimately translates into tangible benefits for Niagara. With high capacity and high utilization of wood, Niagara produces more useful product from its raw material, and reduces labor costs to a great extent.